Everything is customizable: give visibility to your brand

Discover all the printing techniques we employ and their advantages

The peculiarity of our work lies in the ability to customize any desired object. On this page you will find in detail all the printing techniques used by us for customizing company gadgets, clothing and business gifts.

To help you choose and understand, we have highlighted the advantages and limitations of each technology.

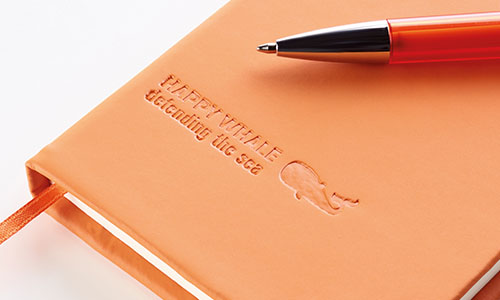

Debossing

The popular technique for leather products is debossing, the logo is first engraved on a metal stamp, then pressed, so it leaves its imprint.

The material chosen must be thick enough to withstand the pressure of the machine, plus it must have a uniform, flat surface.

Advantages

- High-quality 3D appearance

- The print cannot be subsequently removed

Materials

- Cardboard

- Polyurethane

- Leather

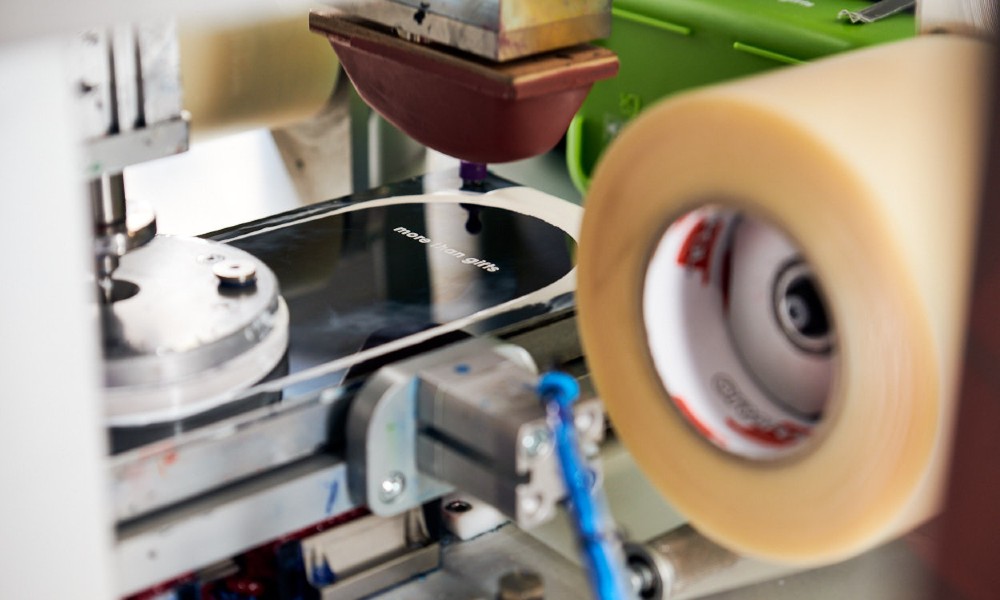

Doming

In doming, the logo is printed on a domed self-adhesive label with a layer of acrylic resin.

The solution is durable and cannot be easily scratched or dented.

Once the labels are combined with the acrylic resin, they are placed in an oven. After the curing stage, the labels are ready to be applied to the item.

Advantages

- Every possible logo shape

- High print quality

- Full colour

Materials

- Leather

- Polyurethane

- Metal

- Plastic

- Wood

- Cardboard

Digital label

A digital sticker print is a digital label, which is applied to a product.

This printing technique is often used when no other technique can be used.

The sticker is cut with a plotter after it has been printed in colour.

The label is peeled off and applied to the articles.

Advantages

- High photo quality

- Full colour

- Every possible logo shape

Materials

- Pile

- Metal

- Felt

- Leather

- Cardboard

- Plastic

- Polyurethane

Laser engraving

Items made of organic material, glass, wood and rubber can be customised by laser engraving.

The result is elegant, precise, clean and permanent. A logo is loaded into a laser machine.

With the hard laser, metals or rigid objects can be marked (fibre laser), with the CO2 laser technique, organic materials can be engraved or marked, and by burning off the top layer, the logo will become permanent.

On cylindrical items such as glass, plastic or metal bottles, 360° laser engraving is possible (only on items without handles).

Advantages

- Permanent printing

- Fine details

- Luxurious printing

- For all materials

- 360° personalisation for clinical items

Materials

- Polyurethane

- Leather

- Felt

- Glass

- Fleece

- Wood

- Aluminium

- Some (hard) plastics

- Paper

- Metal

Silk-screen printing

Ink is transferred onto the article through a frame with many small openings, a stencil will block certain parts to the shape of the logo.

The ink is placed on the frame and poured onto the product, one colour at a time is printed.

Several screens must be used to produce a multi-coloured image or logo.

The product is placed in a drying tunnel to fix the ink on the surface after printing.

In 360° customisation, the same procedure is used and applied to a cylindrical article where the article is slightly rotated to obtain a round print.

Advantages

- All pantone colours

- Large prints

- Higher ink transfer

- All materials

- 360°

Materials

- Plastic

- Polypropylene

- Polystyrene

- Polyethylene

- PVC

- Metal

- Glass

- Ceramic

- Wood

- Paper

- Polyester

- Nylon

- Cotton

Digital Printing

A special UV digital colour printer is used for digital printing. Many dots are fired onto a printable surface, which in combination create the image or a colour.

This type of printing is generally used on flat, even surfaces, as the distance between the print head and the object is fixed. the printer will be able to print in CMYK or white.

On some cylindrical-shaped items, it is possible to apply 360° digital printing.

Advantages

- High photo quality

- Large prints

- Full colour + white

- Edge-to-edge

- Costs: one-off installation

Materials

- Glass

- Paper

- Wood

- Metal

- Polyurethane

- Plastic

Embroidery

In embroidery, several stitches are combined to create the image or logo, this technique is popular and widely used for hats, textiles or bags.

The design details and machine settings are recorded on a specific file.

The product is inserted into a large sewing machine, there are 12 needles (so up to 15 different colours can be embroidered in one step).

Advantages

- Luxurious quality

- Long-lasting

- Maximum of 15 colours

Materials

- Pile

- Cotton

- Polyester

- Nylon

Sublimation

Coloured images can be printed on white, hard surfaces or on polyester-coated items using the sublimation technique (digital printing technique).

Images or logos are printed on sublimation paper with CMYK colour printing. The sheets are then automatically cut.

These sheets are applied to the product using pressure and heat. In this process, the ink is transformed from a solid into gas particles. Subsequently, these will enter the surface of the article.

When the item has cooled, the ink will be fixed inside the item's coating.

Advantages

- High photo quality

- Full colour

- Large prints

- No limits on the use of colours

Materials

- For all materials that are covered by a polyester layer

Pad printing

The pad printing technique uses silicone stamps to print logos and graphics on items.

Its strength is the perfect colour match to the original pantone of the logo, the precision and sharpness of the print.

The logo is engraved on a metal tile, then through a silicone pad it is impressed into the item, the ink does not adhere to the silicone.

Pad printing is the most widely used printing technique, like screen printing each colour must be printed individually.

Advantages

- Printing on a wide variety of materials

- All kinds of shapes can be printed

- All pantone colours

- High definition

Materials

- Plastic

- Polypropylene

- Polystyrene

- Polyethylene

- PVC

- Metal

- Glass

- Ceramic

- Wood

- Paper

Digital transfer

For logos and designs that have a high photographic quality, Digital Transfer is the best method.

CMYK colours are printed on a roll of paper, then a white layer is printed over the areas covered by the colours. In succession, glue is added to allow adhesion to the item.

Through pressure and heat, the image or logo is transferred onto the article.

Advantages

- High photo quality

- Highly detailed

- Large prints

- With brilliant colours

Materials

- Polyester

- Polyurethane

- Softshell

- Cotton

- Nylon

- Felt

- Cardboard

- Leather

Screen transfer

With the screen transfer technique, before the logo is printed on the article, it is printed on a special silicon paper.

On a white base, the colours are individually printed, the whole thing is then passed through a drying tunnel. All colours are printed and only then is a layer of glue added in the same shape as the logo and an adhesive powder applied.

Only with the use of a heat press will the transfer onto the article be finished.

It is heat that will melt the glue, pressure on the other hand will help the adhesion process on the article.

The logo will remain on the article when the paper is removed.

Advantages

- For all materials

- All pantone colours

- Large prints

- Soft touch

Materials

- Polyester

- Cotton

- Softshell

- Polyurethane

- Nylon

- Leather

- Cardboard

- Felt

Ceramic transfer

A print is heat-applied to a ceramic product, this is the process of ceramic transfer.

Your logo will be printed on decal paper, using ceramic inks.

This paper is wrapped around the ceramic item after being immersed in water, which is then kept in an oven for many hours, with temperatures of up to a thousand degrees Celsius.

The print is burnt in the kiln, and the print remains on the ceramic item, this process ensures that the personalisation is permanent and precise.

Advantages

- Dishwasher-proof

- Even on the inside or on the handle of cups

- Large prints

- All pantone colours

Materials

- Glass

- Porcelain

- Ceramic

Digital Inlay

The logo is imprinted on a four-colour (CMYK) printer with digital inlay, which offers photographic quality and sharp text.

The logo is then printed and placed in the chosen position.

Advantages

- Full colour

- High photo quality

Materials

- It is printed on a sheet of paper so the material of the article is not affected

Button printing

This is a digital print on top of a piece of paper that is pressed onto a button. Before the item is assembled, printing is carried out, which allows for a fully customised design.

Advantages

- High quality

- Fully customised design possible

- Full colour

Materials

- On any button, printing on paper